ControlPlex Rack Application scenarios and functionalities

Application Examples

The modular design of the ControlPlex®® Rack system allows perfect adaptation to the respective application requirements.

The combination of various sub-assemblies expands the performance range from purely electronic overcurrent protection to smart, remote-controlled systems with sensor monitoring.

Learn more in our application scenarios.

More examples

-

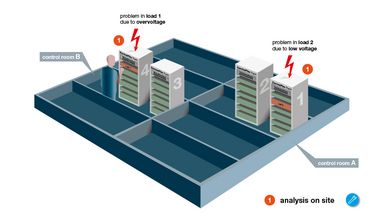

Electronic overcurrent protection with the ControlPlex Rack

Electronic overcurrent protection with the ControlPlex® Rack

The ControlPlex® Rack protects connected loads against overcurrent and short circuit by means of the ESX300-S electronic circuit protectors. The system reliably prevents the destruction of electronic sub-assemblies or load lines. The integral electronic current limitation of the ESX300-S prevents that high currents flow in the event of a short circuit, which could cause a voltage dip of the power supply. If a failure occurs in a load (see example load 1 and load 2) of the system, only the affected load will be disconnected thanks to the selective working principle, and faultless devices in the circuit continue to operate.

Another advantage of the electronic circuit protectors is their precise and finely adjustable trip behaviour, even with long load lines and small cable cross sections. Unlike conventional circuit breakers, the electronic circuit protector does not require a multiple of its rated current to trip. This saves costs thanks to less power required of the power supply or of DC-DC transformers.

-

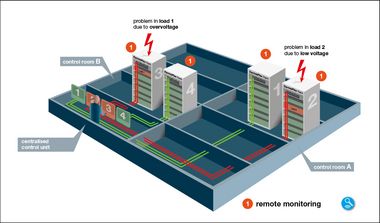

Transparent group signalling with ControlPlex Rack

Transparent group signalling with ControlPlex® Rack

The combination consisting of ControlPlex® Rack, ESX300-S and RSI10 is the entry into transparent monitoring of the connected loads. Via an internal bus, RSI10 communicates with all circuit protectors installed in the ControlPlex Rack. Should one of circuit protectors disconnect the related load due to an overvoltage, overcurrent or similar, the RSI10 will externally indicate this status via a potential-free group signal, e.g. to a control room. This allows immediate corrective action both with isolated applications as well as with centrally monitored systems to remedy the failure.

-

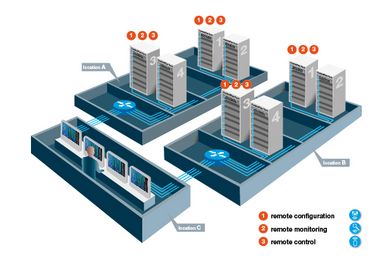

Convenient remote control of the ControlPlex Rack

Convenient remote control of the ControlPlex® Rack

If the ControlPlex® Rack is fitted with ESX300-S and RCI10, the system can simply be integrated into the network environment of the company. This extends the functional scope of the ControlPlex Rack system by smart control and monitoring functions. The internal bus system provides the RCI10 with access to all installed ESX300-S circuit protectors. It is then able to switch connected loads ON or OFF, to force re-starts, query or buffer individual measuring data, status conditions and error messages, and forward them to the central management system or the host PC.

-

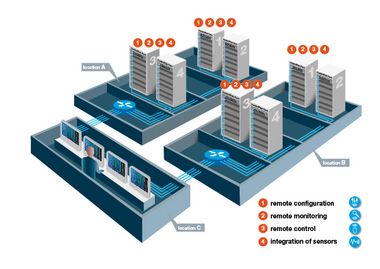

Easy integration of external sensor data with the ControlPlex Rack

Easy integration of external sensor data with the ControlPlex® Rack

The combination of ControlPlex® Rack, ESX300-S, RCI10 and EAI300 is the maximum configuration level of the system. Besides system protection, remote control and monitoring as well as network integration, the connection of external sensors is also available. No matter if temperature monitoring or control of a door contact is required: this combination unites all functions in a single compact 19” system. Thanks to programmable logical links, operating conditions of the ESX300-S can be connected with external encoder signals, allowing actions to be triggered automatically.